The Challenge

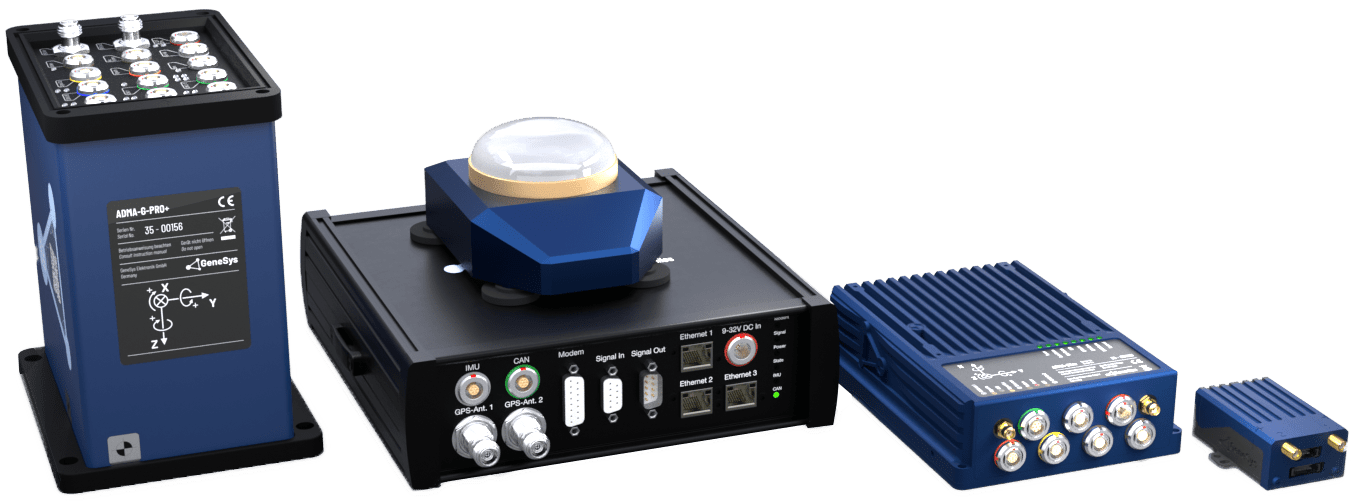

Electrical and electronic systems of modern road vehicles are becoming increasingly complex, which is why manufacturers must validate their safety systems before placing them on the market. The methods of ISO 26262 describe in detail the processes of quality management. Even if all components have been developed, built and secured accordingly, the OEM cannot simply transfer responsibility to the supplier. Ultimately, the OEM will not be able to avoid investigating and documenting the effects of a component defect on the entire vehicle in accordance with the principles of product and manufacturer liability. This sector is called „Functional safety“. The company GeneSys Elektronik GmbH has developed a test and validation system for this purpose.

Motivation

To evaluate the functional safety of a vehicle according to ASIL (Automotive Safety Integrity Level), it is necessary to first assess the probability of occurrence of a risk – the controllability by the driver in the event of a fault event as well as the severity of the hazard to the user or his environment.

This is already done during the development process of the individual components, but must also be applied to the entire vehicle. Modern simulation methods already deliver very good and reliable results here. Even so, there will be no getting around real driving tests, at least on a random basis, to validate and document the results.

Modern vehicles have many areas that can be affected.

Here are just a few examples for systems the functional safety has to be considered.

| Vehicle dynamics control • Lateral acceleration sensor • Yaw rate sensor • Steering angle sensor • Wheel speed sensor | Steering • Steering angle sensor • Steering torque sensor • Power supply • Power modules (such as MOSFET) |

| ADAS and Autonomous driving • Radar • Lidar • Ultrasound • Cameras | Transmission • Faulty switching, incorrect actuation of valves |