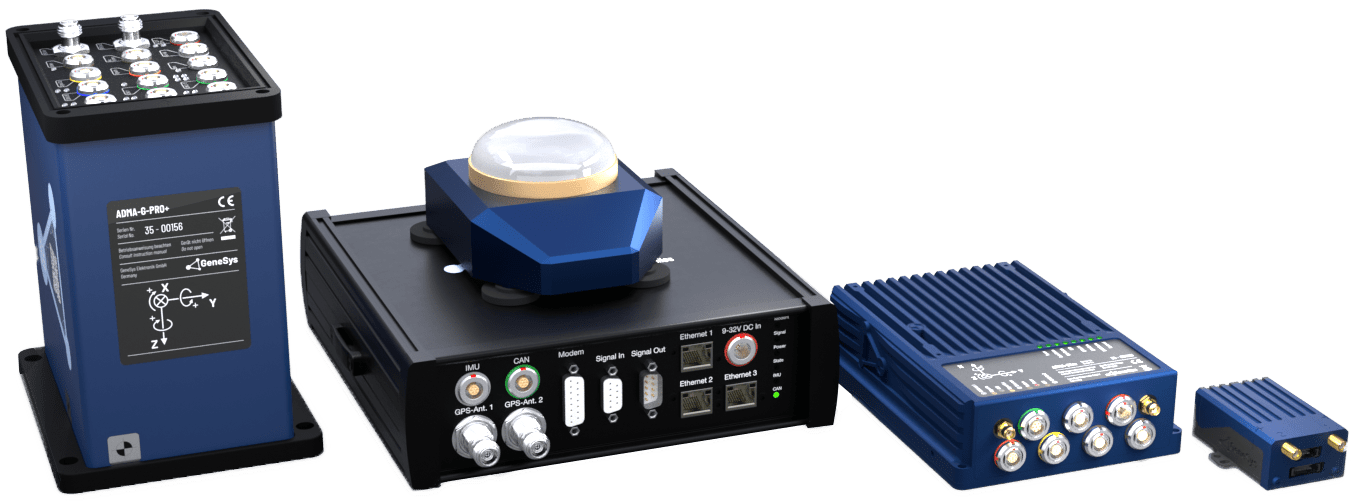

GNSS-aided Inertial Systems

ADMA-G: Pro+/ Eco+/ Eco

ADMA-Speed

ADMA-Slim

ADMA-Micro

Product Overview

DAkkS device testing and calibration

GeneSys is the first DAkkS accredited calibration laboratory according to DIN EN ISO/IEC 17025:2018 for the measurement quantity of velocity in the range 5m/s to 23m/s. The accreditation also covers the measurement quantities of acceleration and angular velocity.

Regular calibration ensures the quality of the products on the basis of internationally comparable measurement results. As a DAkkS accredited service provider, we can develop an individual calibration strategy quickly and efficiently, independent of the device manufacturer.

In addition to the calibration of our ADMA systems, devices from other manufacturers such as Racelogic, Oxford Technical Solutions, Race-Technology, Kistler and many more can now also be calibrated according to DIN EN ISO/IEC 17025:2018.

Outage times are expensive

To eliminate the possibility that the measurement data of tests carried out cannot be used by the customer, all measuring equipment should be calibrated at close intervals of one to two years. Calibration is an important part of measurement hardware maintenance. Regular calibration not only saves time and money but also makes sure that the customer can meet all project requirements.

Compliance with standards

From general quality management systems such as ISO 9001 to requirements that are specifically geared to test and measurement equipment, such as DIN EN ISO/IEC 17025:2018, there are a number of standards that prescribe when calibration is required. A customer with regularly calibrated equipment ensures compliance with the applicable measurement standards.