The challenge

To provide the most secure and shortest braking distance when it comes to emergency traffic situations, OEM and TIER1 intensively develop braking systems. However, the technical possibilities for braking distance optimization are increasingly exhausted, so it is necessary to determine braking distances with high precision and reproducibility.

Therefore the braking measurement system got the following requirements:

- Reliable, accurate and easy usable measurement data

- Compensation of the vehicle pitch during braking process s Easy and quick installation

- Drift compensation at standstill

- Conforming to standards and norms

Braking measurement methods

The braking measurement system has to be really flexible to fit all kind of standards, like ECE R90, 13H or FMVSS135. Therefore, the Addon Braking supports a wide range of configuration possibilities that contain externally triggered braking, velocity triggered braking and fading braking according to DIN70028.

Main braking measurements

Braking via brake pedal trigger

Velocity triggered braking via velocity limits

Triggered Braking via brake pedal trigger

The ADMA-Speed captures the trigger event at the pedal to a nanosecond accuracy. Therefore, an electronical trigger is getting mounted on top of the braking pedal with elastic strips. The external triggered braking distance is getting measured from that exact moment of the brake pedal hit to the configured lower velocity limit with a precision of up to 2 cm.

Windowed Braking via velocity limits

With the function of windowed brake measurement, it is possible to define parallel to triggered braking or exclusive velocity limits. Considering the Doppler effect in combination with inertial sensor technology, it is possible to derive the exact velocity value with high accuracy. As a result, the brake measurement data is output consistently and comparably in order to test the complete brake assembly, i.e. chassis, hydraulics, electronics and tires.

Fading Measurement

The windowed braking data can be output parallelly with two different velocity limits, triggered by the main velocity values and the intermediate velocity values. This functionality also allows to realize fading brake tests. Considering that the ADMA-Speed has to be set up external and velocity triggered with activated “stop at external trigger” and with the intermediate start velocity fitting the main start velocity. With these settings the ADMA-Speed can measure the fading scenarios as well as the final braking event.

Mandatory data

- External triggered braking distance and time s Windowed triggered braking distance and time s Intermediate braking distance and time

- Vehicle velocity

- Velocity at external trigger start

- Vehicle deceleration

- Mean deceleration windowed

- MFDD (Mean Fully Developed Deceleration) s Normalized brake distance

- Estimated brake distance error

Optionally:

- Roll, Pitch and Yaw angle

MFDD (Mean Fully Developed Deceleration)

The MFDD shows the maximum deceleration figure a vehicle can achieve. It is usually the deceleration between 80% and 10% of the trigger activation speed. It describes the time at which the vehicle is loaded up and braking at its highest achievable level.

When the externally triggered braking option is active, the MFDD calculation refers to the velocity at external trigger. If this option is not active, the MFDD calculation refers to the configured start velocity of the velocity triggered braking.

MFDD is calculated by:

MFDD = ((v80%)2 – (v10%)2) / (25.92 * (s10% – s80%))

Where:

v80% is the speed at 80% of the brake trigger activation speed. v10% is the speed at 10% of the brake trigger activation speed. s80% is the distance at which the speed is v80%.

s10% is the distance at which the speed is v10%.

Normalizing velocity

The normalizing velocity is a concept that takes dynamics out of the equation when calculating performance trends.

The normalized braking distance is calculated by: snorm = (vnorm)2 / (2 * am)

Where: snorm am vnorm

snorm is the normalized braking distance.

am is the mean deceleration.

vnorm is the configured normalizing velocity

Solved challenges

There are several challenges for measuring the braking distance accurately:

Lever arm effect

In general, there are different velocities at different measurement points depending on the dynamic of the vehicle. With the beginning of the braking process the vehicle starts to pitch forward rotating around the vehicle COG (Center Of Gravity). Now the MRP (Measurement Reference Point) moves faster than COG. To compensate these lever arm effect the ADMA-Speed is able to output braking data in a POI (Point Of Interest) that is put into the vehicle center of gravity.

Rockback

During a braking maneuver a constant pitch occurs in the vehicle. If the vehicle comes to standstill, the so-called rock-back behavior results until a pitch of zero degrees is reached again. For this reason, a value greater than or equal to 1 km/h must be selected as the lower velocity threshold for a braking distance measurement.

GNSS instability

Sometimes the reception of GNSS satellites signals gets disturbed. In these situations, the accuracy of the braking measurements suffers. With combining GNSS and the IMU it is possible to get a maximum of position accuracy and to compensate GNSS outtakes.

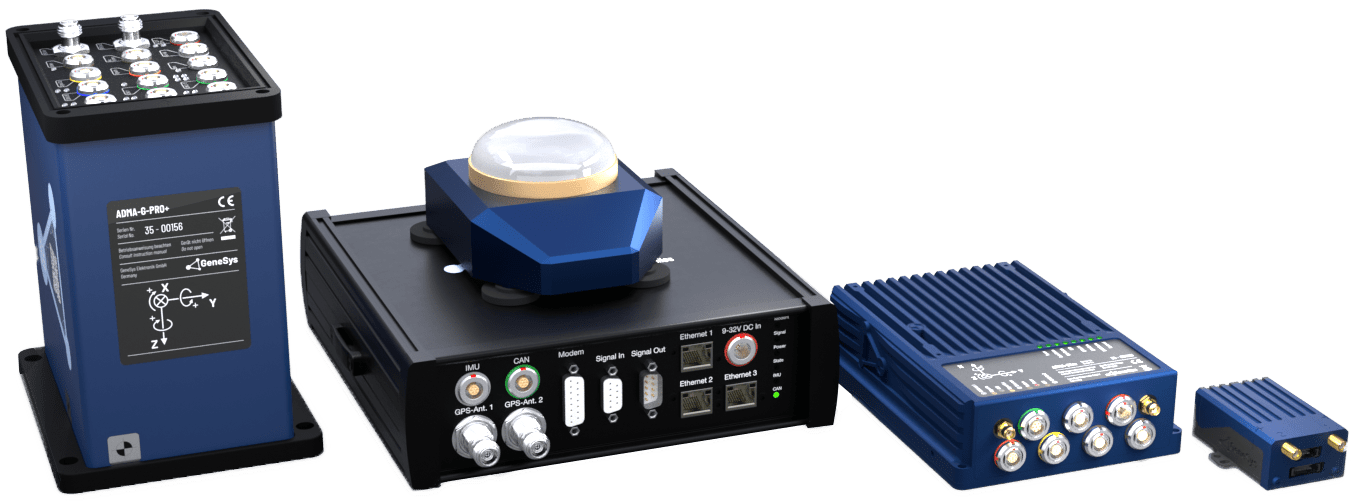

Toolchain

With its strong magnetic feet, the sensor unit of the ADMA-Speed can be easily installed on the roof of the Vehicle Under Test (VUT). The sensor unit combines the GNSS antenna and IMU in a single housing. Therefore, no antenna offset determination is necessary. The data processing unit can be installed anywhere inside of the vehicle.

The entire configuration can be done via an intuitive Web interface. It allows to define start and end limits, external trigger settings and further configuration values.

While testing the braking system the output data of the ADMA-Speed can be visualized in the GeneSys Ethernet Logger. The software signalizes arming limits to the driver visually and via acoustic signals. By displaying a braking table, the Ethernet Logger shows the success of the single braking maneuvers very neat. The recorded data (e.g. arming speed, braking distances, MFDD, yaw, estimated distance error) are easily accessible via spreadsheet for postprocessing and analysis. Furthermore, all measurement data can also be provided in parallel via the CAN interface.

Optionally, ADMA-Speed can be expanded to a full-fledged GNSS-aided inertial system, e.g. for vehicle dynamics testing or verification of ADAS systems.